Milestones:First 500 MeV Proton Beam from the TRIUMF Cyclotron, 1974 and Milestones:16-bit Monolithic DAC, 1981: Difference between pages

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

== Citation == | == Citation == | ||

[[Image:DAC Milestone ceremony.JPG|thumb|right|Honorees at DAC Milestone ceremony, 6 December 2010. Photo copyright: Linda Prazak]] | |||

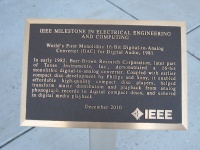

[[File:2008-20 DAC milestone plaque mounted 2.JPG|200px|thumb|left|DAC Milestone plaque mounted outside the door]] | |||

''In early 1982, Burr-Brown Research Corporation, later part of Texas Instruments, Inc., demonstrated a 16-bit monolithic digital-to-analog converter. Coupled with earlier compact disc development by Philips and Sony, it enabled affordable high-quality compact disc players, helped transform music distribution and playback from analog phonograph records to digital compact discs, and ushered in digital media playback.'' | |||

The plaques may be viewed at: | |||

#Texas Instruments' North Dallas campus, Dallas, TX U.S.A. outside the Semiconductor Building that has other TI landmarks installed. The outside location is chosen so that anyone at the building can easily see the milestone and its significance. | |||

#Texas Instruments Building, 5411 East Williams, Blvd., Tucson, Arizona, U.S.A.& where the product design and manufacturing actually happened. | |||

== Historic significance of the 16-bit Monolithic DAC == | |||

The PCM53/DAC700 was the world's first monolithic 16-bit DAC. Designed by Jimmy Naylor and TI / Burr-Brown data converter design team,<ref name="refnum1">"A complete high-speed voltage output 16-bit monolithic DAC", Naylor, J.R.;Solid-State Circuits, IEEE Journal of Volume 18, Issue 6, Dec 1983 Page(s):729 – 735.</ref><ref name="refnum2">"A 16b monolithic DAC with voltage output", Naylor, J.; Solid-State Circuits Conference. Digest of Technical Papers. 1983 IEEE International, Volume XXVI, Feb 1983 Page(s):186 - 187.</ref><ref name="refnum3">United States Patent 4,423,409, Naylor , et al. December 27, 1983. Digital-to-analog converter having single-ended input interface circuit. Inventors: Naylor; Jimmy R. (Tucson, AZ), Lillis; William J. (Tucson, AZ), Wang; Anthony D. (Tucson, AZ). Assignee: Burr-Brown Research Corporation (Tucson, AZ). Appl. No.: 06/250,868. Filed: April 3, 1981.</ref><ref name="refnum4">United States Patent 4,381,497. Lillis , et al. April 26, 1983 | |||

Digital-to-analog converter having open-loop voltage reference for regulating bit switch currents. Inventors: Lillis; William J. (Tucson, AZ), Naylor; Jimmy R. (Tucson, AZ), Wang; Anthony D. (Tucson, AZ), White; Robert L. (Tucson, AZ). Assignee: Burr-Brown Research Corporation (Tucson, AZ). Appl. No.: 06/250,858. Filed: April 3, 1981. PCM53 datasheet</ref> this product played a key role in transforming the music industry from analog audio tapes and vinyl long play discs (LPs) into digital audio compact discs. This 16-bit DAC was designed in to almost all major manufacturers of CD players when the compact disc player was emerging as a superior digital audio apparatus and led TI / Burr-Brown to dominate the digital audio data converter market with more than 80% share for several years. The TI/ Burr Brown DAC was mentioned in the movie “The Italian Job”. This unique monolithic chip and its fundamental achievement together with the technical advances in audio and speech processing, digital signal processing, which occurred in the 1970s and 1980s,<ref name="refnum5">Gene Frantz and Larry Zhang, TI IEEE Electrical Engineering and Computing Milestone nomination: Speak & Spell – the first implementation of a Digital Signal Processing IC for speech generation, 1978.</ref> resulted in digital audio<ref name="refnum6">IEEE milestone to N.V. Philips for "COMPACT DISC AUDIO PLAYER, 1979".</ref> overtaking analog audio and spawning a new digital audio industry that is still expanding today with the introduction of a new generation iPods and other MP3 players. | |||

For the first time, a complete 16-bit monolithic DAC had been integrated into a single chip with all the components necessary for a high performance digital to analog converter. Up until this point all 16-bit DACs were multi-chip hybrids that are not functionally complete because external components must be added and they were very costly to build. When Sony and Philips were designing the digital audio players, there were three fundamental problems that needed to be solved: | |||

#A medium that could store the amount of information needed for high fidelity audio. They started with digital tape, but settled on the compact disc (CD) format. | |||

#Lowering the cost of the read mechanism (laser) to read the CD. | |||

#A low cost, high performance DAC to play back the music! | |||

The | TI / Burr-Brown’s design team were already working on a monolithic DAC for industrial markets, but the TI / Burr-Brown team stepped up the pace and were first to the emerging audio market. The differential linearity laser trim algorithm made the DAC "sound better” with lower Total Harmonic Distortion (THD) that was better than if you trimmed for absolute linearity. This was the best performance audio DAC of its time with much improved reliability over the older hybrid design which required multiple chips and over 100 wirebonds. With the help of TI/Burr-Brown Japan’s super sales and applications team the 16-bit monolithic converter DAC was designed in to almost all major manufacturers of CD players and dominated the digital to analog audio converter market with more than 80% share for several years. | ||

and | |||

To reduce a multichip hybrid converter design to a single chip, several obstacles had to be overcome in the late 1970’s or early 1980’s: Power consumption changes on a single chip will cause thermal gradients that affect temperature sensitive components introducing offset, gain, and/or linearity errors. Since thermal gradients on the chip surface take a few hundred microseconds to stabilize after a power change, the settling time of the DAC output could be adversely affected. This phenomenon is sometimes referred to as a thermal settling “tail.” Minimizing the die size precluded the use of large capacitor values that is common in a hybrid design, for the compensation of amplifiers or for suppressing switching transient. To realize the new single chip monolithic DAC, and holding the die size to less than 20,000 square mils to minimize the cost per die, required an innovative process technology. Rather than using a conventional 40 V bipolar process used for many analog circuits, a thinner epi process yielding 20 V BVCEO transistors was chosen. This saved considerable die area as typical transistor geometries are approximately 50 percent smaller. | |||

== References == | |||

<references /> | |||

== Letter from the site owner giving permission to place IEEE milestone plaque on the property. == | |||

[[Media:RichTempleton_Letter_for_16Bit_DAC_milestone.pdf|Milestone Support Letter]] | |||

== Proposal and Nomination == | |||

[[Milestone-Proposal:16-bit Monolithic DAC]] - Proposal, submitted 2008 | |||

[[Milestone-Nomination:16-bit Monolithic DAC, 1981]] - Nomination, submitted June 8th, 2009 | |||

== Map == | |||

== | |||

== | {{#display_map:32.21713, -110.87787~ ~ ~ ~ ~Texas Instruments, Tucson, AZ|height=250|zoom=10|static=yes|center=32.21713, -110.87787}} | ||

[[Category:Consumer electronics|Dac]] [[Category:Signals|Dac]] [[Category:Signal processing|Dac]] [[Category:Digital signal processing|Dac]] | |||

[[Category: | [[Category:Digital_signal_processing|{{PAGENAME}}]] | ||

Revision as of 19:16, 6 January 2015

Citation

In early 1982, Burr-Brown Research Corporation, later part of Texas Instruments, Inc., demonstrated a 16-bit monolithic digital-to-analog converter. Coupled with earlier compact disc development by Philips and Sony, it enabled affordable high-quality compact disc players, helped transform music distribution and playback from analog phonograph records to digital compact discs, and ushered in digital media playback.

The plaques may be viewed at:

- Texas Instruments' North Dallas campus, Dallas, TX U.S.A. outside the Semiconductor Building that has other TI landmarks installed. The outside location is chosen so that anyone at the building can easily see the milestone and its significance.

- Texas Instruments Building, 5411 East Williams, Blvd., Tucson, Arizona, U.S.A.& where the product design and manufacturing actually happened.

Historic significance of the 16-bit Monolithic DAC

The PCM53/DAC700 was the world's first monolithic 16-bit DAC. Designed by Jimmy Naylor and TI / Burr-Brown data converter design team,[1][2][3][4] this product played a key role in transforming the music industry from analog audio tapes and vinyl long play discs (LPs) into digital audio compact discs. This 16-bit DAC was designed in to almost all major manufacturers of CD players when the compact disc player was emerging as a superior digital audio apparatus and led TI / Burr-Brown to dominate the digital audio data converter market with more than 80% share for several years. The TI/ Burr Brown DAC was mentioned in the movie “The Italian Job”. This unique monolithic chip and its fundamental achievement together with the technical advances in audio and speech processing, digital signal processing, which occurred in the 1970s and 1980s,[5] resulted in digital audio[6] overtaking analog audio and spawning a new digital audio industry that is still expanding today with the introduction of a new generation iPods and other MP3 players.

For the first time, a complete 16-bit monolithic DAC had been integrated into a single chip with all the components necessary for a high performance digital to analog converter. Up until this point all 16-bit DACs were multi-chip hybrids that are not functionally complete because external components must be added and they were very costly to build. When Sony and Philips were designing the digital audio players, there were three fundamental problems that needed to be solved:

- A medium that could store the amount of information needed for high fidelity audio. They started with digital tape, but settled on the compact disc (CD) format.

- Lowering the cost of the read mechanism (laser) to read the CD.

- A low cost, high performance DAC to play back the music!

TI / Burr-Brown’s design team were already working on a monolithic DAC for industrial markets, but the TI / Burr-Brown team stepped up the pace and were first to the emerging audio market. The differential linearity laser trim algorithm made the DAC "sound better” with lower Total Harmonic Distortion (THD) that was better than if you trimmed for absolute linearity. This was the best performance audio DAC of its time with much improved reliability over the older hybrid design which required multiple chips and over 100 wirebonds. With the help of TI/Burr-Brown Japan’s super sales and applications team the 16-bit monolithic converter DAC was designed in to almost all major manufacturers of CD players and dominated the digital to analog audio converter market with more than 80% share for several years.

To reduce a multichip hybrid converter design to a single chip, several obstacles had to be overcome in the late 1970’s or early 1980’s: Power consumption changes on a single chip will cause thermal gradients that affect temperature sensitive components introducing offset, gain, and/or linearity errors. Since thermal gradients on the chip surface take a few hundred microseconds to stabilize after a power change, the settling time of the DAC output could be adversely affected. This phenomenon is sometimes referred to as a thermal settling “tail.” Minimizing the die size precluded the use of large capacitor values that is common in a hybrid design, for the compensation of amplifiers or for suppressing switching transient. To realize the new single chip monolithic DAC, and holding the die size to less than 20,000 square mils to minimize the cost per die, required an innovative process technology. Rather than using a conventional 40 V bipolar process used for many analog circuits, a thinner epi process yielding 20 V BVCEO transistors was chosen. This saved considerable die area as typical transistor geometries are approximately 50 percent smaller.

References

- ↑ "A complete high-speed voltage output 16-bit monolithic DAC", Naylor, J.R.;Solid-State Circuits, IEEE Journal of Volume 18, Issue 6, Dec 1983 Page(s):729 – 735.

- ↑ "A 16b monolithic DAC with voltage output", Naylor, J.; Solid-State Circuits Conference. Digest of Technical Papers. 1983 IEEE International, Volume XXVI, Feb 1983 Page(s):186 - 187.

- ↑ United States Patent 4,423,409, Naylor , et al. December 27, 1983. Digital-to-analog converter having single-ended input interface circuit. Inventors: Naylor; Jimmy R. (Tucson, AZ), Lillis; William J. (Tucson, AZ), Wang; Anthony D. (Tucson, AZ). Assignee: Burr-Brown Research Corporation (Tucson, AZ). Appl. No.: 06/250,868. Filed: April 3, 1981.

- ↑ United States Patent 4,381,497. Lillis , et al. April 26, 1983 Digital-to-analog converter having open-loop voltage reference for regulating bit switch currents. Inventors: Lillis; William J. (Tucson, AZ), Naylor; Jimmy R. (Tucson, AZ), Wang; Anthony D. (Tucson, AZ), White; Robert L. (Tucson, AZ). Assignee: Burr-Brown Research Corporation (Tucson, AZ). Appl. No.: 06/250,858. Filed: April 3, 1981. PCM53 datasheet

- ↑ Gene Frantz and Larry Zhang, TI IEEE Electrical Engineering and Computing Milestone nomination: Speak & Spell – the first implementation of a Digital Signal Processing IC for speech generation, 1978.

- ↑ IEEE milestone to N.V. Philips for "COMPACT DISC AUDIO PLAYER, 1979".

Letter from the site owner giving permission to place IEEE milestone plaque on the property.

Proposal and Nomination

Milestone-Proposal:16-bit Monolithic DAC - Proposal, submitted 2008

Milestone-Nomination:16-bit Monolithic DAC, 1981 - Nomination, submitted June 8th, 2009