Wire Drawing and Bridges

This article was initially written by Robert Woods, ASME Fellow. This article contains material published in Mechanical Engineering Magazine Feb. 2012. Copyright 2012 American Society of Mechanical Engineers

In 1726, the English satirist Jonathan Swift posed a question: How might a race of tiny creatures immobilize an enormously larger human being? The answer, as learned to his distress by Gulliver, was by binding him with a large number of thin cords; the miniature people were incapable of handling a single rope big enough to secure a human.

Roughly a century later, John Roebling asked the same question. He planned a suspension bridge that would require cables that were far too long and weighed far too much to simply pick up and emplace. The solution was to divide the cables into manageable pieces; in this case, wire three-sixteenths of an inch in diameter. Six thousand such wires went into each cable. A recently developed ability to produce wire in unlimited lengths made the bridge possible.

Machines for wire drawing have an ancient history, although until recent centuries they were limited to producing wire in fairly short lengths. The origin of wire drawing tools has been traced to well before 2000 Before Common Era. The earliest examples are found in Egypt where gold wire was drawn to make jewelry.

Anywhere in the spectrum between making jewelry and building bridges, the work starts with an elongated metal billet which has been shaped by hand working or machine rolling. One end is reduced to a diameter that will pass through a funnel-shaped die which is typically circular although it is possible to extrude other cross sections.

The small end of the billet is pulled ("drawn"), forcing the metal to be elongated and reduced in diameter. This can only be done with a metal that is normally ductile or which has been heated to ductility.

Drawing usually takes place in several steps and the product can be variously treated between stages. This might involve softening or plating.

Lubricants are applied in almost every case although very ductile metals such as gold were drawn without lubrication, sometimes through holes in gem stones. In some cases lubrication is accomplished by plating the base with another, even more ductile, metal.

Plating can be chosen not only to lubricate but also to give a finished wire useful surface properties like the tinplated copper wire used in electronics. The plating prepares the wires for soldering.

A valuable side effect of wire drawing is that cold-working aligns the metal grains and raises the tensile strength of most alloys; this hardening is not an unmixed blessing. It usually demands heat treating between stages to soften or increase ductility.

Wire making machines were a major source of income for John A. Roebling even before he used them to reap a bonanza in wire rope. Roebling, founder of a dynasty, was a colorful example of the giants of engineering of his era. By coincidence, he was born in the same year as the famous British engineer l.K. Brunel.

Roehling was a Prussian emigrant who had studied many aspects of architecture and engineering, including the design of suspension bridges, before he came to the United States. Oddly enough, it was not engineering that brought him to North America. He had hoped to found an agricultural colony.

That scheme proved to be a failure. After it foundered he returned to surveying and bridge building, relying heavily on his favorite structure, the suspension bridge. He turned to wire production and then to using wire to make rope. Roehling designed a series of progressively larger suspension bridges. It was the reputation that he acquired from those smaller bridges that allowed him to bid on the East River bridge, as the project was originally called.

A true proponent of hands-on management, he died of injuries received while surveying the area where his bridge would stand. He only saw the very earliest stages of construction. The bridge was completed by his son, Washington Roehling, and his son's wife, Emily, who was a very competent engineer in her own right.

Emily did a brilliant job of managing the program when Washington was later incapacitated by the bends, which he acquired by working in the pressurized submarine chambers where the footings were being laid. Chambers of that sort are the source of an alternate name for the bends, caisson disease.

Another member of the family, Washington's brother Charles, designed and constructed an eighty-ton wire rope machine, which is an ASME engineering landmark largely because of its sheer size. This machine is still in existence in Trenton, N.J.

The cables for the Brooklyn Bridge weigh 870 tons and are 3,577 feet long. They are composed of individual longitudinal wires, mechanically integrated by circumferential winding after being hung. This winding took the form of a close-wound wrap of more 3/16-inch diameter wire. The overwrap was painted with white lead to make the assembly watertight, corrosion being the principal enemy of any iron or steel structure.

Assembling a group of wires so as to distribute the stress equally is a problem in materials science as well as statics. The modulus of elasticity was held within close tolerances. That was important when a load was to be uniformly distributed among a myriad of wires.

The wires were also specified to have an ultimate stress of 160,000 psi. This is low by today's standards, where a nominal figure for tensile strength is in the vicinity of 250,000 psi. When the bridge was being built each wire was tensioned so as to hang in a catenary paralleling the already installed wires. The alignment was verified by workmen moving alongside the unfinished bundle on a separate cable-suspended platform. Since the wires were specified to be equally elastic by controlling the modulus of elasticity, they would be trusted to assume equal loads.

Numerous ingenious mechanical fixtures have been developed to lock in the pretensioning in parallel wires. In some cases wires are assembled into smaller bundles which are anchored in fixtures resembling chucks and collets. In other cases, each wire is pretensioned individually and a terminal swaged on the end. Evolution of this detail goes on today. This is important in prestressed concrete that is in wide use.

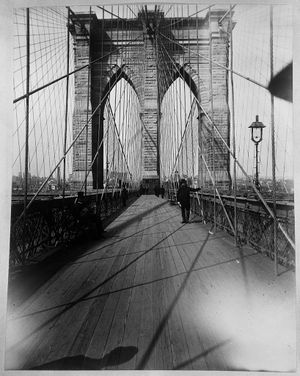

In the Brooklyn Bridge a pedestrian deck was suspended independently of the main bridge structure. An examination of drawings or photos of the bridge shows a web of thin cables radiating from the tops of the pylons. These are not part of the basic structure. This spider web actually supports the pedestrian deck which is a bridge within a bridge.

The independent bridge was the precursor of a style of construction which came into its own right in the 1950s and is beginning to supplant the traditional suspension bridge. This style of construction is referred to as "cable-stayed."

Just as iconic as the Brooklyn Bridge, which has become a symbol of all suspension bridges, is the Rion-Antirion bridge at the west end of the Gulf of Corinth in Greece. Until recently it was the world's longest example of cable-stayed bridges.

It is an interesting case of technology being foreshadowed by ancient history. Since classic times, events in the Mediterranean world were shaped by the fact that Greece is divided into a northern and a southern region by the Gulf of Corinth. Any traffic between the two had to pass along a narrow isthmus between the Gulf and the Mediterranean (actually the Sea of Candia).

Whoever controlled that spit of land was in a position to levy exorbitant tariffs on traffic. That had the effect of making the city of Corinth notoriously wealthy; a fact that was decried during biblical times. Any one wishing to pass north to south had little choice as to his route.

The only alternative to the isthmus was to take a small ship between two ports at the west end of the gulf. These ports are at cities named Rion and, logically enough, Antirion. They have given their names to the modern bridge.

In early days, taking a boat across the patch of water between these ports was not an attractive alternative to land travel. The currents in that passage were notoriously treacherous and the wind undependable.

In recent times, the currents have been tamed by large ferry boats, but boats are still a poor substitute for uninterrupted traffic. After being an obstacle since classical times the strait was spanned in 2004 by a bridge. That bridge is a monument to the art of wire drawing.

It also happens to be a major engineering accomplishment in other ways. The geology in the vicinity is subject to tectonic activity, so each pylon becomes a problem in dynamics as well as statics. Each has a sway-damping pendulum. Another consideration is that the seabed is not well suited to structural foundations. Thus special footings were designed. Because of the distance between pylons it is unlikely that an older style of bridge could have made the span.

The cable-stayed form of bridge not only offers advantages during erection, but it also allows more leeway in pylon design than the traditional suspension structure. The pylons do not have to fall into the single plane defined by sagging cables as is the case in suspension bridges.

Designers have exploited this freedom and have produced designs that are intentionally novel and aesthetically pleasing. Engineers are free to indulge in fanciful and elegant pylon shapes.

Present day wire stay construction differs radically from the bundled wires of the Brooklyn Bridge, but it shares a common problem. Cables must be protected from the weather. Today they are usually enclosed in tubes of metal or polyethylene which are backfilled after emplacement. This is typically done with concrete, but occasionally with some elastomeric material. Poly tubes can be colored to give a pleasing appearance.

Since the deck is supported over its entire length, cable staying offers construction advantages. It is possible to assemble the deck in a series of segments, each of which can be slid into place over already-installed portions.

Unlike suspension bridges where the deck is supported by vertical wires attached to the catenaries, support is provided by the vertical component of force in a series of diagonals. This introduces another design consideration. The deck has to resist in compression the horizontal component of the forces in a number of diagonal wires.

Such a deck is commonly a concrete slab with pre-stressed wire reinforcement. Preloading such wires before the deck is installed is essentially the same handling problem as fine-tuning the stays.

The span of a bridge dwarfs its human creators to an even greater extent than Gulliver dwarfed the Lilliputians, but bridges, too, depend on numerous cords of a manageable size. The fact that these metal sinews are possible can be traced back more than 4,000 years.

The technology to create them was handed through generations of wire-drawing machines. It originated with the unnamed craftsman who first recognized that a metal billet could be hand worked into a totally new shape. The tools that he used were small and primitive, and they depended on nothing more than manual strength.

Over millennia, hand tools have evolved into sophisticated and powerful machines but the same principles that allowed gold billets to be transformed into a pharaoh's jewelry now make it possible to build the bridges that carry immense loads across miles of water.

Further Reading

The importance of wire drawing in today's industry is best appreciated by referring to the web page of the Wire Association International: http://www.wirenet.org/vts/vts_search.cfm.

This page gives access to an exhaustively indexed library of information on wire drawing. Thanks are due to Marc Murray of WAI for bringing this to the author's attention.

The Brooklyn Bridge was well documented in 1877, six years before completion, by Cable-Making For Suspension Bridges: With Special Reference To The Cables Of The East River Bridge, By William Hildenbrand. This is available as a photocopy from Nabu Public Domain Reprints.

Cable-stayed bridges are documented in numerous publications. Two of the best are Cable-Stayed Bridges, M.S. Troitsky, BSP Professional Books, London, 1988 and Cable Stayed Bridges, R. Walther, et. al, T. Telford, London, 1988.